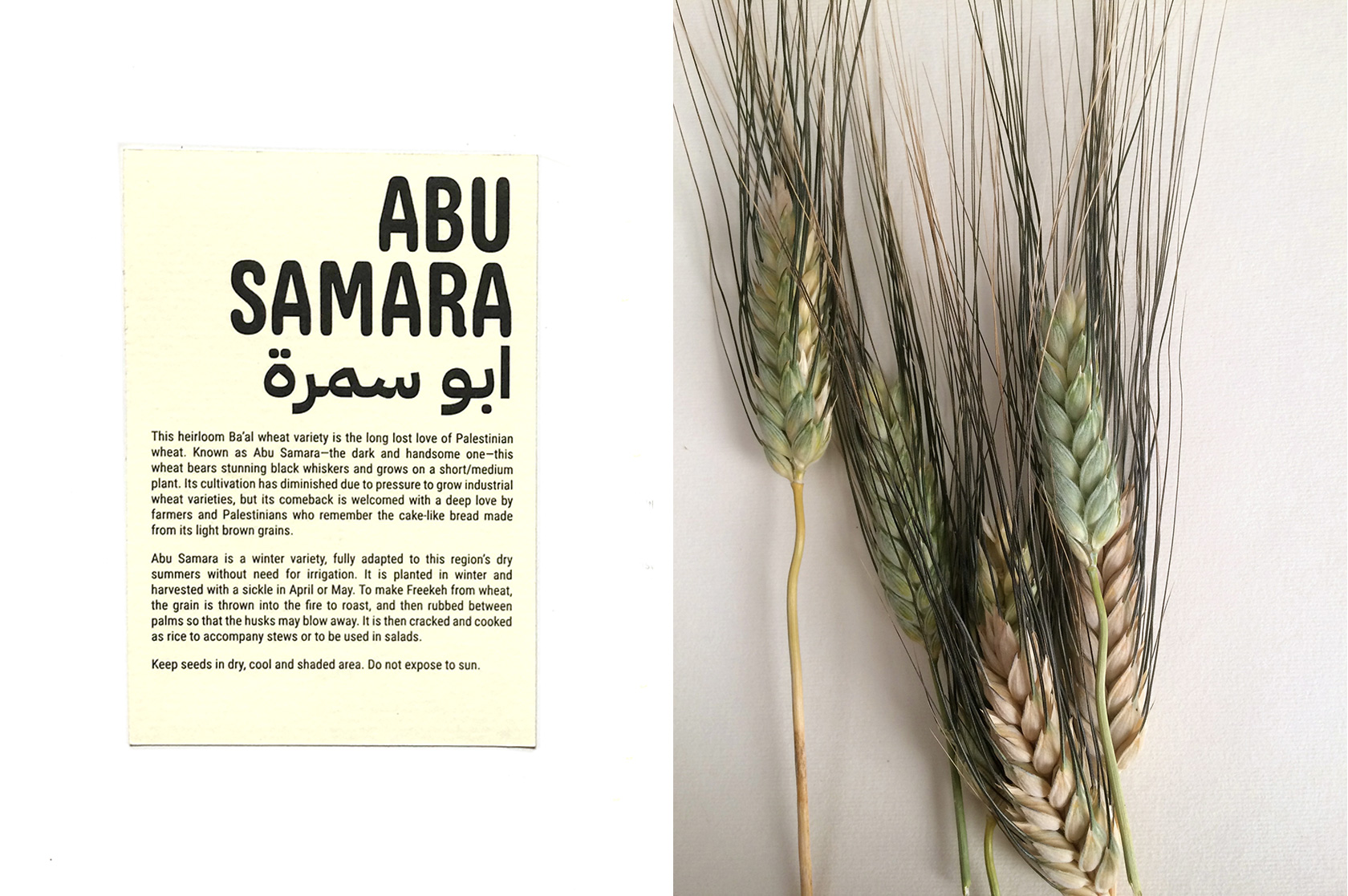

Tears

دموع

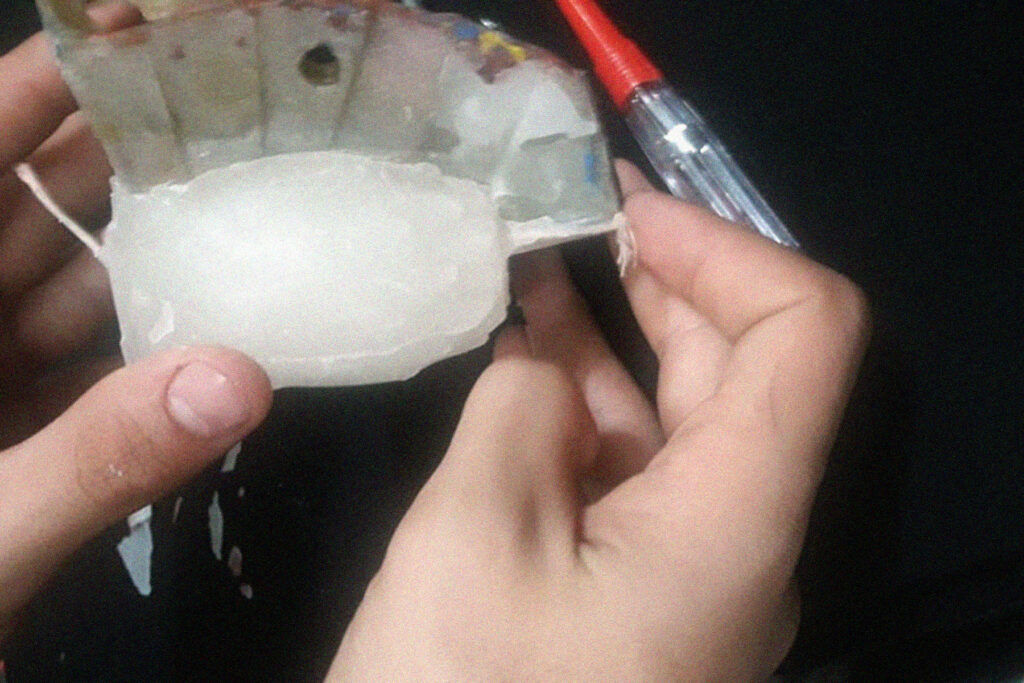

These tender hand-blown glass tears are rooted in a centuries-old tradition of glass production in Al-Khalil / Hebron. It is part of a bountiful craft industry established in the city during Roman rule. Traditionally, the glass was melted using local raw materials, including sand from neighbouring villages, sodium carbonate from the Dead Sea, and colouring additives such as iron oxide and copper oxide. Nowadays, recycled glass is often the way to go.

Glass production is a family trade, the secrets of which have been preserved and passed down by a few Palestinian families operating the glass factories just outside the city. “One of the things that make this family workshop strong is the relationship between the family members. Everybody that is working here is really passionate about what they are doing, and they really want to see it continue as a tradition for the Palestinians,” according to Hamzeh Natsheh, one of the owners of the family-run workshop. But glass production suffered from a forced decline, and running the workshop is getting harder and harder: “Since 2001 and the beginning of the Second Intifada, things changed rapidly, and there were restrictions on the businesses all over Palestine,” Natsheh adds*.

- Further reading:

- * Despite the hurdles, Hebron glass makers keep the kiln fires burning [Middle East Eye]

- Creating Colorful Waves Of Phoenician Glass: Hebron Glass [Cultural Survival]

- Hebron Glass & Ceramics Factory (PS)

The tradition of glassblowing continues today in three factories just north of the city, a short distance between the town of Halhul and Hebron. Two of the factories are owned by the Natsheh family. They produce primarily souvenirs, most of which are also used as household items. A large hall close to each of the factories displays wine glasses, dishes, bowls, flower pots, and other products. Although most objects are not decorated, some have artistically applied glass strings. Metallic decoration is a recent innovation of the industry.

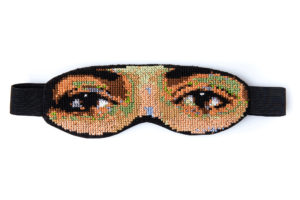

Glass beads for jewellery have traditionally been made in Hebron. Blue beads and glass beads with ‘eyes’ (owayneh) were made and used as amulets since they were considered particularly effective against the evil-eye.

In the old city’s Al-Kazazin quarter (Kazazin meaning ‘people who make glass’), three families operated 14 glass factories. Today, there are only two of them left, run by the Natsheh family. The first Intifada, combined with the affluence of cheap goods from China and the rise in oil prices forced the majority of glass shop owners out of business. Both remaining factories have relocated to the entrance of the city, because tourists are sometimes fearful to go too deep into the old city.

Mr. Hamdi – who runs the Hebron Glass & Ceramics Factory together with his brother -started working when he was 17, in 1967. Nowadays, he exclusively deals with administrative aspects, but he is still capable to tell which one of his workers did which piece just by looking at it. The savoir-faire is passed down from father to son, but some are more talented than others and each glass-blower insufflates his own personal touch into his work. The job is hard, sitting seven hours a day next to an over 1000°C hot oven. Workers learn from early childhood and continuously refine the skill. Hebron Glass is the leading product of those companies. The name originally applied to the national hand-crafted, mouth-blown glass named in Arabic Zujaj Nafakh. Because the color blue is a cultural favorite in the Arab world, Hebron Glass came to describe the blue glass products, both the light turqoise blue (copper blue) and the deep royal blue (cobalt blue). The factories also specialize in a Middle Eastern favorite, Imzakhraf, which is a dot-painted, Arabesque design technique on traditional blown glass.

Recycled glass

6 cm

€7,50